VMI Group

Education & Research

VMI Group

Education & Research

Built an App to send messages

from the machine to the Vuzix smart glass

Built an App to send messages

from the machine to the Vuzix smart glass

ABOUT

About VMI

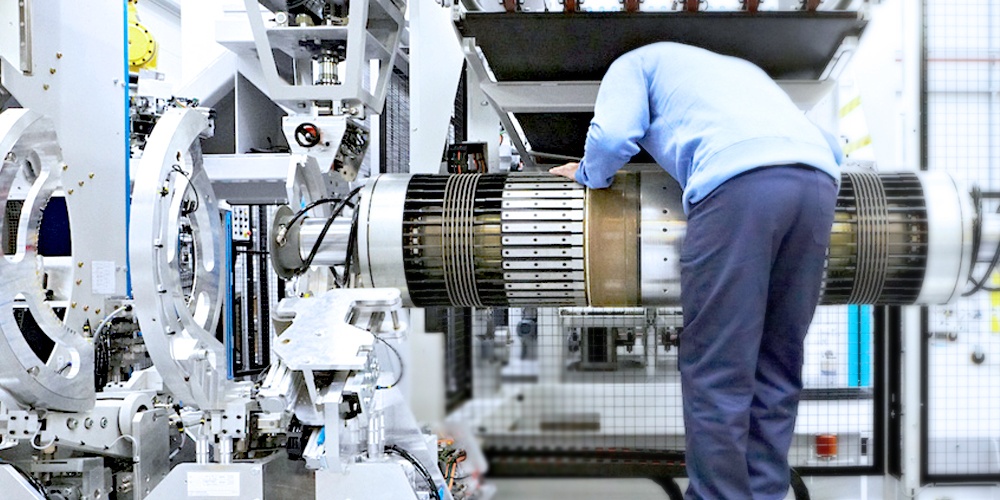

About 1600 VMI people around the world continuously work on high-tech, innovative solutions to make your company more successful. Since its foundation in 1945, VMI has expanded into a modern company with nine facilities on four continents, providing proven, reliable equipment, services and solutions.

VMI’s headquarters based in Epe, the Netherlands, employs about 900 people. Through experienced and highly skilled people and an ambitious and enterprising management team, VMI is acknowledged as a respected market leader offering innovative machinery that contains about 1600 VMI people around the world continuously working on high-tech, innovative solutions to make your company more successful. Since its foundation in 1945, VMI has expanded into a modern company with nine facilities on four continents, providing proven, reliable equipment, services and solutions.

VMI’s headquarters based in Epe, the Netherlands, employs about 900 people. Through experienced and highly skilled people and an ambitious and enterprising management team, VMI is acknowledged as a respected market leader offering innovative machinery that is continuously developed and further enhanced. continuously developed and further enhanced.

Challenge

A machine of VMI can potentially create a lot of messages in the PLC, some messages are relevant, and others are not that relevant. First VMI spent a lot of time to streamline the message queue, to assure a created message makes sense. A message can be triggered when raw material/sub-assemblies quantities are low, finished goods buffers are full, or when there is an issue with the machine. Until now an operator/engineer got a light/sound signal something is wrong and at that moment he needs to go to the HMI of the machine first to read the message. This cost valuable time and it happened also often that an operator saw the message for an engineer, which an operator cannot solve. In the end, a lot of time was lost causing unnecessary downtime of the machine and this is what VMI what’s to ppreventsto assure the high output of the machine.

ABOUT

About VMI Group

About 1600 VMI people around the world continuously work on high-tech, innovative solutions to make your company more successful. Since its foundation in 1945, VMI has expanded into a modern company with nine facilities on four continents, providing proven, reliable equipment, services and solutions.

VMI’s headquarters based in Epe, the Netherlands, employs about 900 people. Through experienced and highly skilled people and an ambitious and enterprising management team, VMI is acknowledged as a respected market leader offering innovative machinery that contains about 1600 VMI people around the world continuously working on high-tech, innovative solutions to make your company more successful. Since its foundation in 1945, VMI has expanded into a modern company with nine facilities on four continents, providing proven, reliable equipment, services and solutions.

VMI’s headquarters based in Epe, the Netherlands, employs about 900 people. Through experienced and highly skilled people and an ambitious and enterprising management team, VMI is acknowledged as a respected market leader offering innovative machinery that is continuously developed and further enhanced. continuously developed and further enhanced.

Challenge

A machine of VMI can potentially create a lot of messages in the PLC, some messages are relevant, and others are not that relevant. First VMI spent a lot of time to streamline the message queue, to assure a created message makes sense. A message can be triggered when raw material/sub-assemblies quantities are low, finished goods buffers are full, or when there is an issue with the machine. Until now an operator/engineer got a light/sound signal something is wrong and at that moment he needs to go to the HMI of the machine first to read the message. This cost valuable time and it happened also often that an operator saw the message for an engineer, which an operator cannot solve. In the end, a lot of time was lost causing unnecessary downtime of the machine and this is what VMI what’s to ppreventsto assure the high output of the machine.

Solution

Recreate has built an App for the Vuzix smart glass to send messages from the machine directly to the glass. Recreate also made a location positioning system so the Revolute will always know who the closest available engineer is to send the message to. Using I-beacon technology we always know the location of the engineer and send this to the PLC of the machine. As soon as an error message pop-up on the HMI of the machine automatically the closest engineer is found, and the message is pushed to this engineer. The big benefit is that the engineer does not first have to go to the HMI to see the error message, he is directly “navigated” to the right part of the machine. The message remains visible on his smart glass, and because his hands are free, he can directly start solving the issue. With this innovative technology, the customers of VMI can operate machines with the need for less staff.

Solution

Recreate has built an App for the Vuzix smart glass to send messages from the machine directly to the glass. Recreate also made a location positioning system so the Revolute will always know who the closest available engineer is to send the message to. Using I-beacon technology we always know the location of the engineer and send this to the PLC of the machine. As soon as an error message pop-up on the HMI of the machine automatically the closest engineer is found, and the message is pushed to this engineer. The big benefit is that the engineer does not first have to go to the HMI to see the error message, he is directly “navigated” to the right part of the machine. The message remains visible on his smart glass, and because his hands are free, he can directly start solving the issue. With this innovative technology, the customers of VMI can operate machines with the need for less staff.

Discover our Projects in

Manufacturing