Thomas Regout

Manufacturing Industry

Thomas Regout

Manufacturing Industry

Provide them the tool to create complex work instructions.

ABOUT

About Thomas Regout B.V.

Thomas Regout International B.V. offers a broad range of telescopic sliding solutions that help move your application in any direction: horizontal, vertical and diagonal. Next to our ball bearing telescopic slides we are also a manufacturer of linear guides and different systems and features that can be used together with our drawer slides. Our customer engineers are pleased to help you with solutions to move your product either vertically or horizontally.

To be and to remain your best partner in telescopic slides we have made some major improvements in our factory in Maastricht. Whether you think of robotics, interconnected IT systems, short lead time, high-quality products, or a fully controlled production process, we are ready for the future! By incorporating the highest quality standards like IATF 16949 for the automotive industry, ISO 9001, and different environmental certifications like ISO 14001, Reach and RoHS we ensure that our products and services are safe, reliable, sustainable and of high quality.

With our knowledge and experience, we help our customers to stay far in front of the competition. Our technical knowledge combined with the use of high-quality materials and an extensive quality control program, allows us to develop high-quality products.

By listening and by exploring the latest technology innovations we identify our customers’ current and future needs and turn these market demands into innovative sliding solutions. The use of advanced production methods and sustainable materials ensures optimal quality.

Challenge

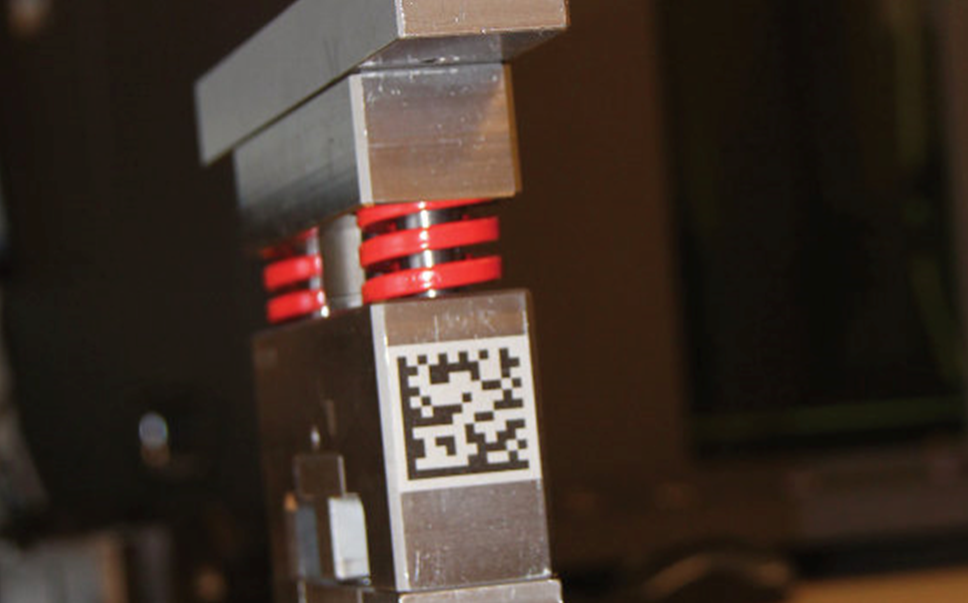

Thomas Regout created a wide variety of telescopic slides, and these products are made based on customer requirements. For every production order several tools are needed to form the raw material (steel) to a telescopic slide. Currently a dedicated team of tool makers assemble and disassemble the tools. The process is difficult to learn (a long training period is needed) and the process is labor intensive. Thomas Regout is looking for a tool to capture the knowledge of the toolmakers in a system and to have a visual tool te reduce margin for error during the assembly of tools. Another goals is to have a user friendly tool allowing other people than toolmakers to created tools in case of high demand.

ABOUT

About Thomas Regout B.V.

Thomas Regout International B.V. offers a broad range of telescopic sliding solutions that help move your application in any direction: horizontal, vertical and diagonal. Next to our ball bearing telescopic slides we are also a manufacturer of linear guides and different systems and features that can be used together with our drawer slides. Our customer engineers are pleased to help you with solutions to move your product either vertically or horizontally.

To be and to remain your best partner in telescopic slides we have made some major improvements in our factory in Maastricht. Whether you think of robotics, interconnected IT systems, short lead time, high-quality products, or a fully controlled production process, we are ready for the future! By incorporating the highest quality standards like IATF 16949 for the automotive industry, ISO 9001, and different environmental certifications like ISO 14001, Reach and RoHS we ensure that our products and services are safe, reliable, sustainable and of high quality.

With our knowledge and experience, we help our customers to stay far in front of the competition. Our technical knowledge combined with the use of high-quality materials and an extensive quality control program, allows us to develop high-quality products.

By listening and by exploring the latest technology innovations we identify our customers’ current and future needs and turn these market demands into innovative sliding solutions. The use of advanced production methods and sustainable materials ensures optimal quality.

Challenge

Thomas Regout created a wide variety of telescopic slides, and these products are made based on customer requirements. For every production order several tools are needed to form the raw material (steel) to a telescopic slide. Currently a dedicated team of tool makers assemble and disassemble the tools. The process is difficult to learn (a long training period is needed) and the process is labor intensive. Thomas Regout is looking for a tool to capture the knowledge of the toolmakers in a system and to have a visual tool te reduce margin for error during the assembly of tools. Another goals is to have a user friendly tool allowing other people than toolmakers to created tools in case of high demand.

Solution for the integration of 3D models.

Thomas Regout strategically invested in the Recreate Step-by-step-instruction (SBSI) platform to have a no-code platform to create immersive work instructions. Thomas Regout investigated other solutions in the past (like projection), but these solutions didn’t meet the expectations. The main reason why Thomas Regout selected the SBSI platform from Recreate is the integration with 3D models. A step file can be imported into the SBSI platform, and this will be the basis for the work instruction. Using drag and drop and pre-defined options a non-technical person can create immersive instruction on the fly. Steps can be made and from the 3D model elements can be selected and animated. This basis, combined with some customer features developed for Thomas Regout, will provide them the tool to create (and store) complex work instructions to assemble to tools needed for production. The SBSI platform will be integrated with the MES system of Thomas Regout, allowing the users to work in one system and have the SBSI information available when they need it.

Solution for the integration of 3D models.

Thomas Regout strategically invested in the Recreate Step-by-step-instruction (SBSI) platform to have a no-code platform to create immersive work instructions. Thomas Regout investigated other solutions in the past (like projection), but these solutions didn’t meet the expectations. The main reason why Thomas Regout selected the SBSI platform from Recreate is the integration with 3D models. A step file can be imported into the SBSI platform, and this will be the basis for the work instruction. Using drag and drop and pre-defined options a non-technical person can create immersive instruction on the fly. Steps can be made and from the 3D model elements can be selected and animated. This basis, combined with some customer features developed for Thomas Regout, will provide them the tool to create (and store) complex work instructions to assemble to tools needed for production. The SBSI platform will be integrated with the MES system of Thomas Regout, allowing the users to work in one system and have the SBSI information available when they need it.

Discover our Projects in

Manufacturing