Voortman Staal

Construction & Engineering

How Voortman Staal Uses HoloLens for Precision Quality Inspection

About Voortman Staal

Voortman Staal, founded in 1968 is a steel processing machinery and automation company headquartered in Rijssen, the Netherlands. Over the years, they have established themselves as a leader in the steel processing industry thanks to their innovative machinery and integrated software solutions. Their goal is to be a partner for a business that not only delivers machines, but a complete solution for the industry.

Some of their key projects include the Voortman Fabricator, an automated welding robot, and DIGI-WELD, a tool for automating welding preparation.

The Challenge

Voortman Staal’s challenge was ensuring the accuracy and the quality of their machinery. Traditional methods required manual measurements and visual checks, which were time consuming and also left room for human error.

As such, they needed a more efficient and precise solution. Something that would allow them to instantly compare the built machinery to the original design. This would help them detect any possible discrepancies early to reduce the cost of rework and ensure the best quality for their products.

The Solution – Enhancing Quality Control with HoloLens

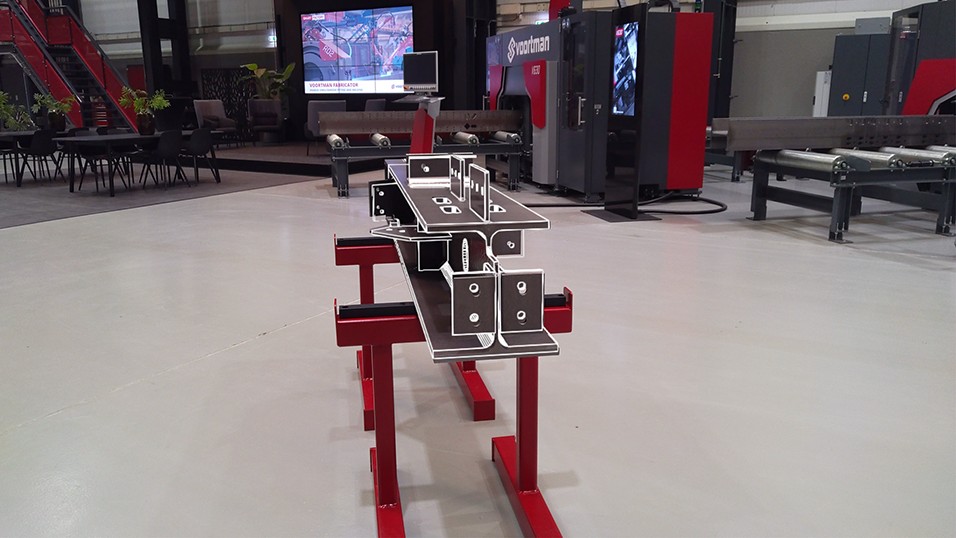

To tackle this challenge for Voortman Staal, we developed a HoloLens Quality Inspection tool. This tool allows users to overlay original design drawings directly onto their steel constructions. It uses augmented reality so that inspectors can see even the smallest deviations in real time to ensure precision down to the millimeter.

The tool is fully integrated with Voortman’s backend system. This means that it automatically loads the correct drawings for each user. This allows for effortless inspections where teams can check alignment, placement and overall accuracy without manual measurements.

Multiple devices were tested to see which one would be best and in the end, the HoloLens proved to be the most effective for this task. HoloLens offers the accuracy and usability that makes it the perfect tool for this situation. Moreover, using AR for quality control greatly reduces human errors, speeds up inspection processes and also ensures that the constructions always meet the highest standards.

Discover our Projects in

Construction & Engineering