Industrial Metaverse – what it is and why it matters

The industrial metaverse has the potential to revolutionize the way we work, connect, and collaborate by providing an unprecedented level of interactivity and experiential knowledge. With its capabilities, businesses can unlock new efficiencies, elevate customer service, and create innovative solutions for the workplace. In short, the industrial metaverse is the next generation of digital transformation, offering unparalleled opportunities to unlock greater insights and efficiencies.

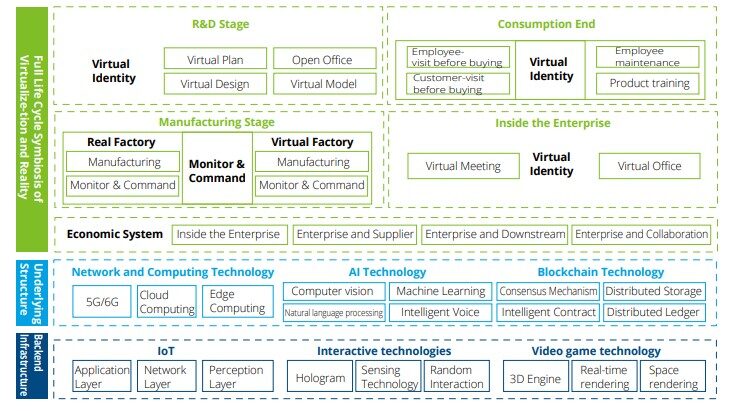

Below a nice overview made by Deloitte of the different technologies and use-cases being used to set-up an industrial metaverse.

Digital Twins and their role in the Industrial Metaverse

Digital twins are at the core of the industrial metaverse. Simply put, a digital twin is a virtual replica of a product or process used to predict how the physical entity will perform throughout its lifecycle. BMW, for instance, created a virtual twin of its production plant in Bavaria before building the physical facility. Boeing is using a digital twin development model to design its airplanes.

By leveraging advanced analytics and simulation capabilities, digital twins allow companies to gain comprehensive insights about their operations and create an environment for virtual collaboration. Through digital twins, businesses can monitor performance across multiple locations, identify areas of improvement in real-time, and collaborate more effectively with customers and partners.

Impact of Extended Reality (XR) applications

Extended Reality (XR) applications combines virtual reality (VR), augmented reality (AR), and mixed reality (MR) technologies into a single, immersive platform. Through XR, users can interact with 3D models and simulations in real-time, providing a more interactive and engaging experience. XR can be used to create virtual training scenarios, 3D product visualization product, employee onboarding, machine maintence and more.

How XR and Digital Twins can be used together

By combining XR with digital twins, companies can gain a deeper understanding of how their operations are performing in real-time and make data-driven decisions. Utilizing digital twins and XR technology to create an industrial metaverse can bring numerous benefits, such as enabling workers to perform augmented maintenance with detailed step-by-step visual instructions on a Hololens projected over the machinery they’re working on.

Recreate 3DX Platform

With our 3DX Platform Recreate is able to support multiple of those scenarios, we for exampled helped Remeha, a climate specialist in the Netherlands, with a Hololens 2 training application. New workers get assembly instructions on the Hololens, resulting in less standstills of the production line.

Challenges in creating an Industrial Metaverse

Creating a metaverse can be a daunting task, as there are many complexities to consider. For instance, embedding digital twins into the existing systems and environments of a company can require time-consuming processes that may not always yield successful results. Additionally, ensuring data privacy and security while managing thousands of users in an industrial metaverse can also present challenges. Furthermore, effectively deploying XR applications in an industrial environment requires a high level of technical know-how and skill to successfully implement the necessary tools and technologies. Despite these hurdles, with proper planning and execution, companies can reap tremendous benefits from creating an industrial metaverse.

How far can the Industrial Metaverse go?

The Metaverse has the potential to revolutionize how manufacturers operate. By leveraging digital twins and XR technology, companies can gain-time insights into their operations and collaborate more effectively with customers and partners. With this advanced system in place, businesses can unlock greater productivity and efficiency, allowing them to keep up with the ever-changing demands of the market.

The implications of an industrial metaverse are far-reaching, from improved customer service to a competitive edge in the industry. Ultimately, it is important for manufacturers to understand the advantages of investing in digital twin models and XR technology to ensure they remain competitive in an increasingly connected world.